Registered Country

Environmental Categories

Best Practice and Technology

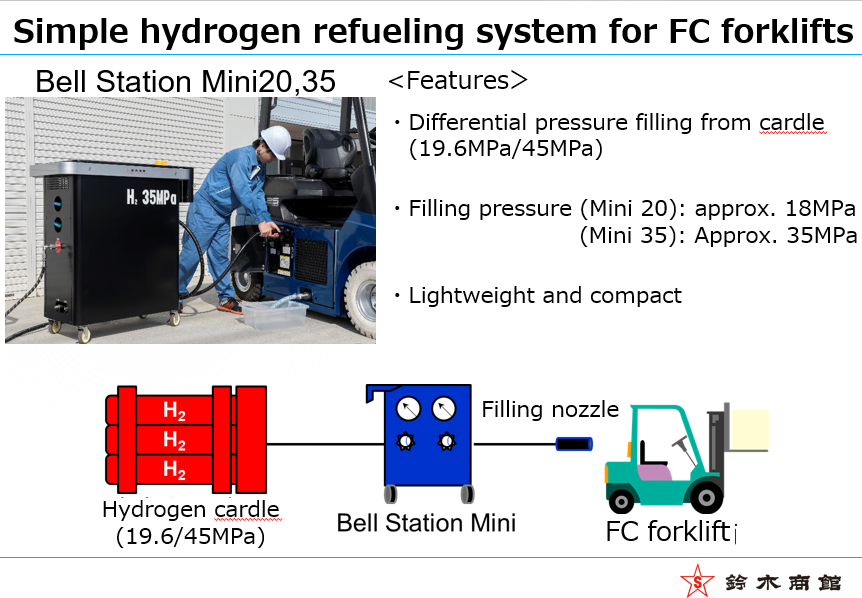

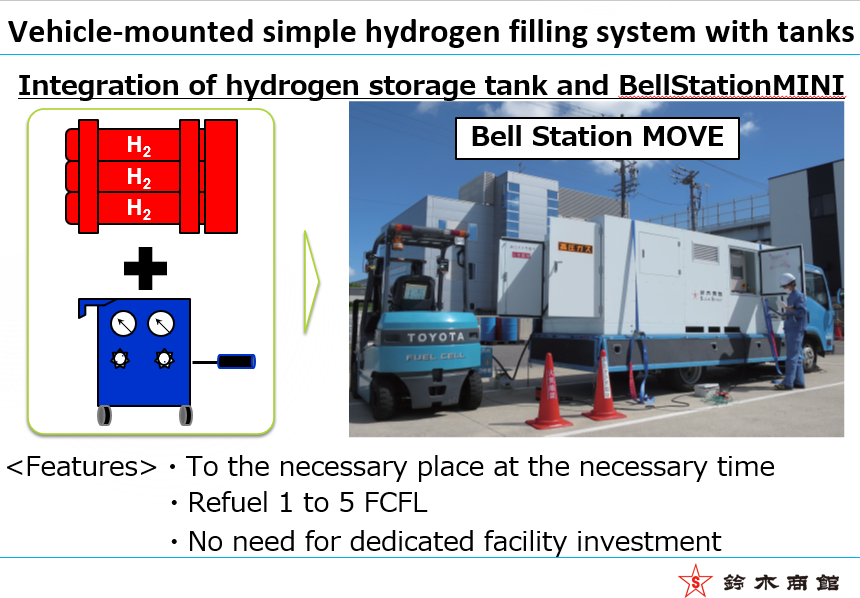

・Filling of FC forklift trucks is possible.

・Smaller and less expensive than installing a hydrogen

station

・Hydrogen can also be delivered.

(Abstract)

Hydrogen is a clean energy source that does not emit CO2 when used, so the use of FC forklifts can contribute to the decarbonization of airports. In addition, hydrogen has a high calorific value per unit weight and can be stored and transported for long periods of time, so FC forklift trucks can be used as emergency power sources.

Implementation Cost

Maintenance Cost

Registered Country

Environmental Categories

Best Practice and Technology

CERA-DUCT protects essential communication and power lines, supporting critical infrastructure with its compact design and modular system. Engineered for life cycle cost efficiency, it offers an environmentally friendly solution made from sustainable materials. With excellent compressive strength, long-term durability, and a time-saving installation process, it ensures cost-effective underground cable protection.

(Abstract)

Ceramic underground duct system that compactly accommodates multiple cables. With exceptional durability, it maintains its shape and quality for long-term use, proven by over 60 years of continuous application in Japan.

Implementation Cost

Maintenance Cost

Registered Country

Environmental Categories

Best Practice and Technology

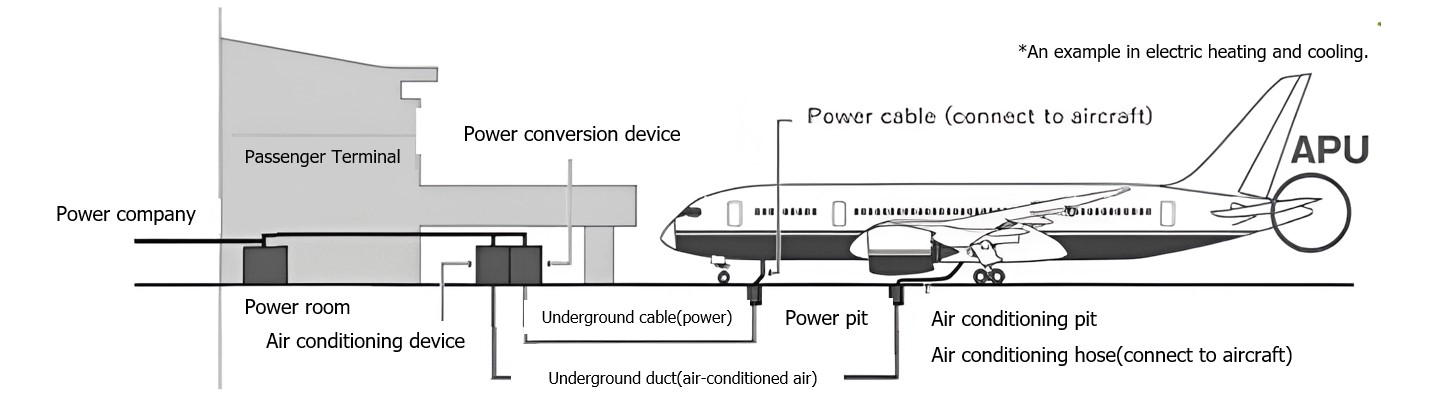

The Fixed-Type Underground GPU/PCA system is an advanced

method for supplying electricity and air-conditioned air

to parked aircraft. It is designed to replace conventional

Auxiliary Power Units (APUs), aligning with global efforts

to reduce CO2 emissions and improve airport operational

efficiency. This technology is recognized as a superior

and environmentally friendly solution developed in

Japan.

Purpose

The primary objective of this system is to provide parked

aircraft with a stable and efficient source of electrical

power and air conditioning without relying on APUs, which

contribute significantly to CO2 emissions. By embedding

the system underground, it enhances safety, efficiency,

and aesthetics at airport aprons.

Features

• Eco-Friendly: Reduces CO2 emissions to

approximately 1/10 of those generated by APUs.

• Safety Improvement: Eliminates the risk of

accidental contact by removing the need for mobile supply

vehicles.

• Operational Efficiency: Provides a quicker

connection time compared to mobile units.

• Aesthetic Enhancement: The underground installation

prevents obstruction and preserves apron landscapes.

• Durability: Embedded pipes have long-lasting

usability, almost perpetual in operation.

• Energy Efficiency: The conditioning air supply is

less affected by external temperatures, improving energy

conservation.

Effects and Advantages

• Environmental Benefits: Supports CO2 reduction

policies and aligns with global sustainability efforts.

• Enhanced Safety: Reduces the presence of ground

vehicles, lowering accident risks.

• Improved Airport Operations: Faster connection

times contribute to smoother aircraft servicing.

• Infrastructure Longevity: Durable underground

components reduce the need for frequent replacements or

maintenance.

• Better Airfield Aesthetics: Removes visible clutter

from the apron area, improving the airport’s overall

appearance.

The Fixed-Type Underground GPU/PCA system is installed in

multiple Japanese airports, with approximately 600 units

deployed across nine airports.

This system exemplifies Japan's technological innovation

in the aviation industry, contributing to more sustainable

and efficient airport operations.

(Abstract)

The Fixed-Type Underground GPU/PCA system supplies electricity and air conditioning to parked aircraft, reducing CO2 emissions by 90% compared to APUs. It enhances safety by eliminating mobile units, improves operational efficiency with faster connections, and preserves airport aesthetics. The system is durable, energy-efficient, and widely implemented in Japanese airports.

Implementation Cost

Maintenance Cost

Registered Country

Environmental Categories

Best Practice and Technology

Unlike general human waste, aircraft sewage is mixed with antimicrobial agents, coloring agents, and in cold regions, anti-freeze solution to prevent freezing. In addition, various treatments are required, such as separation and disposal of contaminants and paper in sewage, prevention of pathogens such as infectious diseases, decolorization, and deodorization. Therefore, we perform advanced treatment to remove nitrogen and phosphorus and dilute and sterilize sewage in consideration of the environment, and treat it to a level that meets sewer discharge standards at our facility.

(Abstract)

The SD plant at Haneda Airport, completed in March 2020, has increased treatment capacity by 1.5 times that of the old plant. It is equipped with waterproofing measures to prepare for high tides and an advanced treatment facility to remove nitrogen and phosphorus with the introduction of a membrane filtration system.

Implementation Cost

Maintenance Cost

Registered Country

Environmental Categories

Best Practice and Technology

1. Efficient refueling: By pumping aviation fuel through

underground pipes directly underneath the aircraft, the

use of refueling tankers can be reduced and refueling can

be completed quickly. In addition, after aviation fuel is

transported by sea, large amounts of fuel can be refueled

safely and quickly.

2. Improved safety: Using underground piping reduces the

risk of accidents caused by aboveground fuel

transportation and increases safety.

3. Reducing environmental impact: Reduces carbon dioxide

emissions emitted by fuel tanker trucks, reducing the

burden on the environment.

(Abstract)

The purpose is to speed up refueling operations, reduce the risk of accidents during fuel transport on the ground, and reduce carbon dioxide emissions from the operation of fuel tanker trucks.

Maintenance Cost

Registered Country

Environmental Categories

Best Practice and Technology

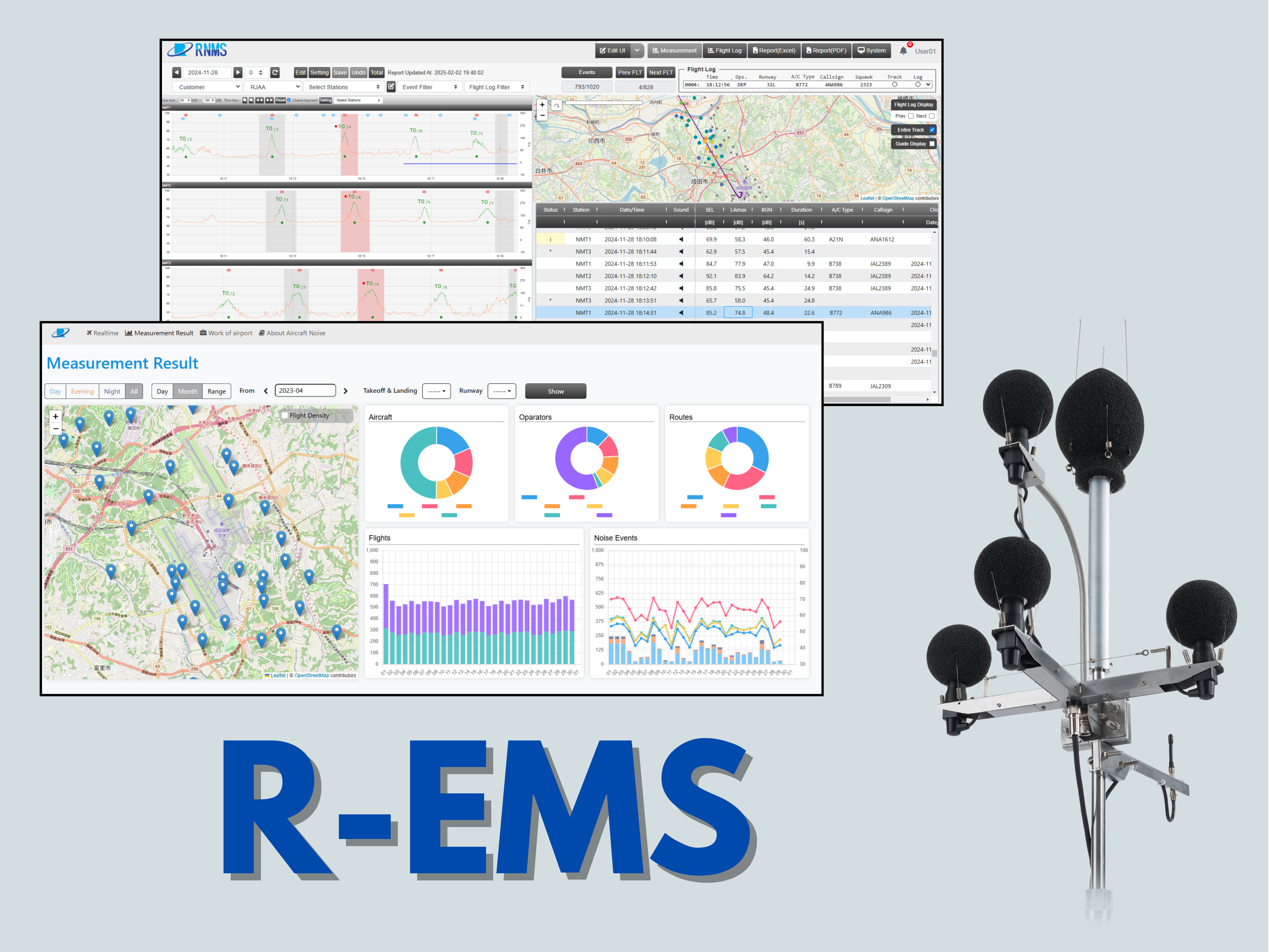

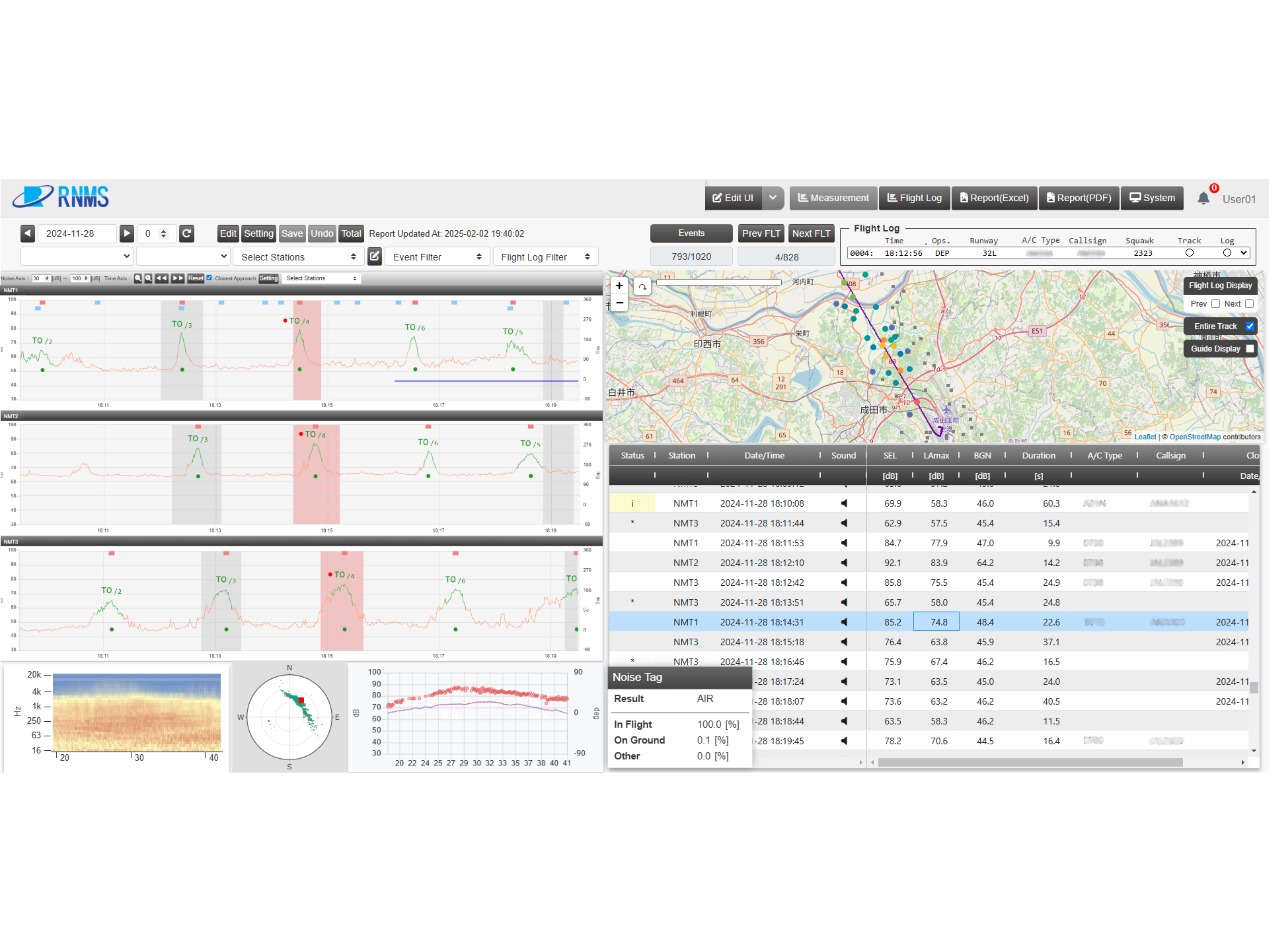

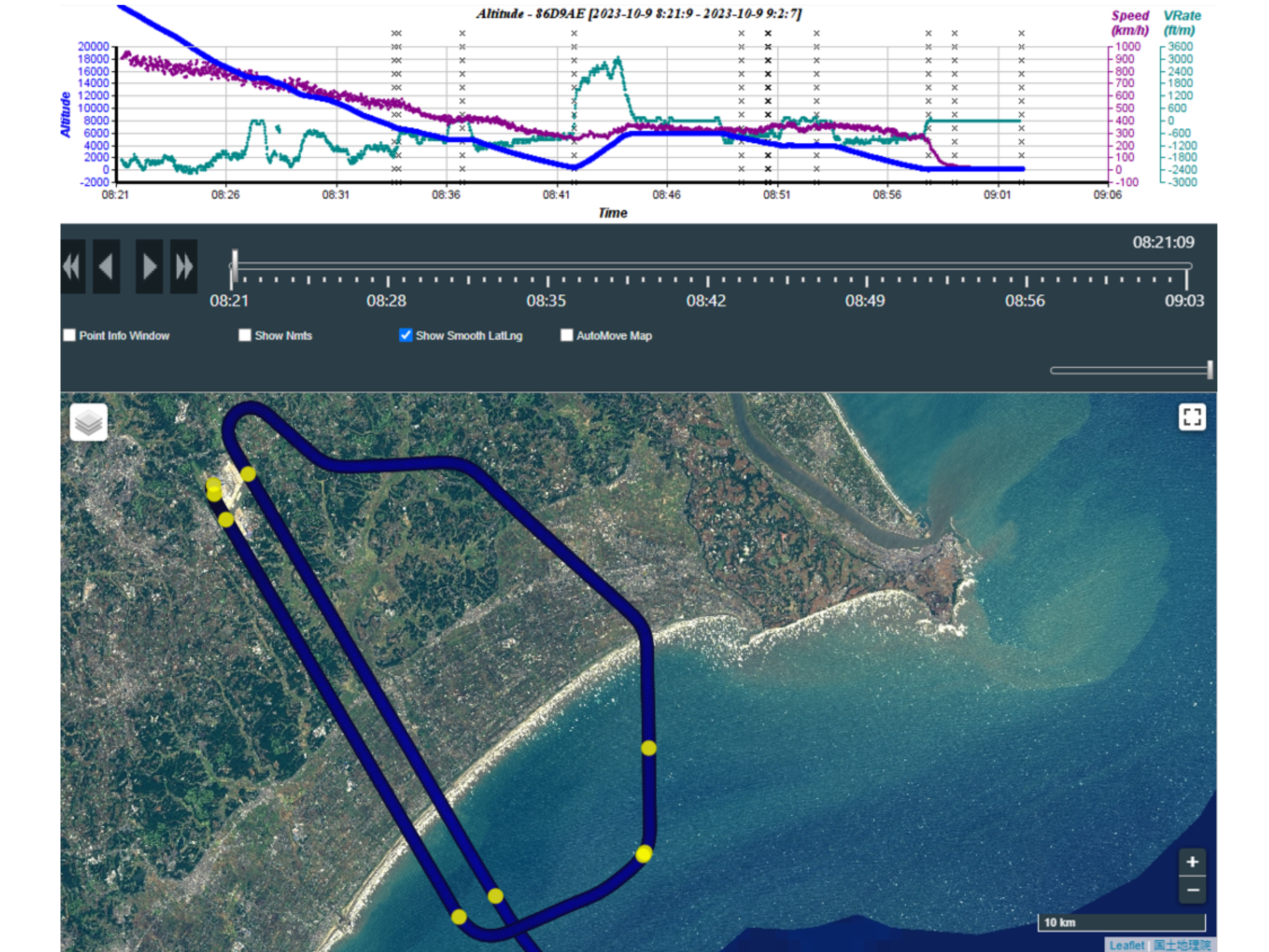

R-EMS is the solution to support airport environmental

department to manage environmental noise assessment.

The evaluation of noise exposure situation around airports

throughout the year will be beneficial for environmental

assessment and countermeasures against aircraft noise.

Flight tracking information can also be useful to consider

flight times and flight routes.

"Publication portal website which can introduce

environmental measures, noise monitoring, and other

initiatives being implemented by the airport.

Real-time publication of noise and flight-track

information on the map is visually explanatory and will

greatly contribute to building trust with

residents."

Features:

・Acquire aircraft noise report with detailed aircraft

information.

Observe flight tracking data using ADS-B and PSSR even in

situations where radar data from airport cannot be

provided.

・PSSR (Passive Secondary Surveillance Rader) is RION's

unique technology, which can observe flight-tracking

information for all aircraft including one without

ADS-B.

・Sound Arrival Direction information can identify the

noise events even when there are large noise sources other

than aircraft nearby, or when it is difficult to identify

noise events by flight tracks.

・Special microphone with excellent weather resistance,

allowing accurate measurements even in the rainy and humid

climate.

(Abstract)

R-EMS is the comprehensive solutions including measurement

instrument and software for airport to manage noise and

build relationships with surrounding community.

"Noise data collected by multiple noise monitoring

terminals which are placed around the airport, will be

integrated into cloud database together with flight track

information, METAR and flight log."

This allows accurate evaluation for aircraft noise.

Implementation Cost

Maintenance Cost

Registered Country

Environmental Categories

Best Practice and Technology

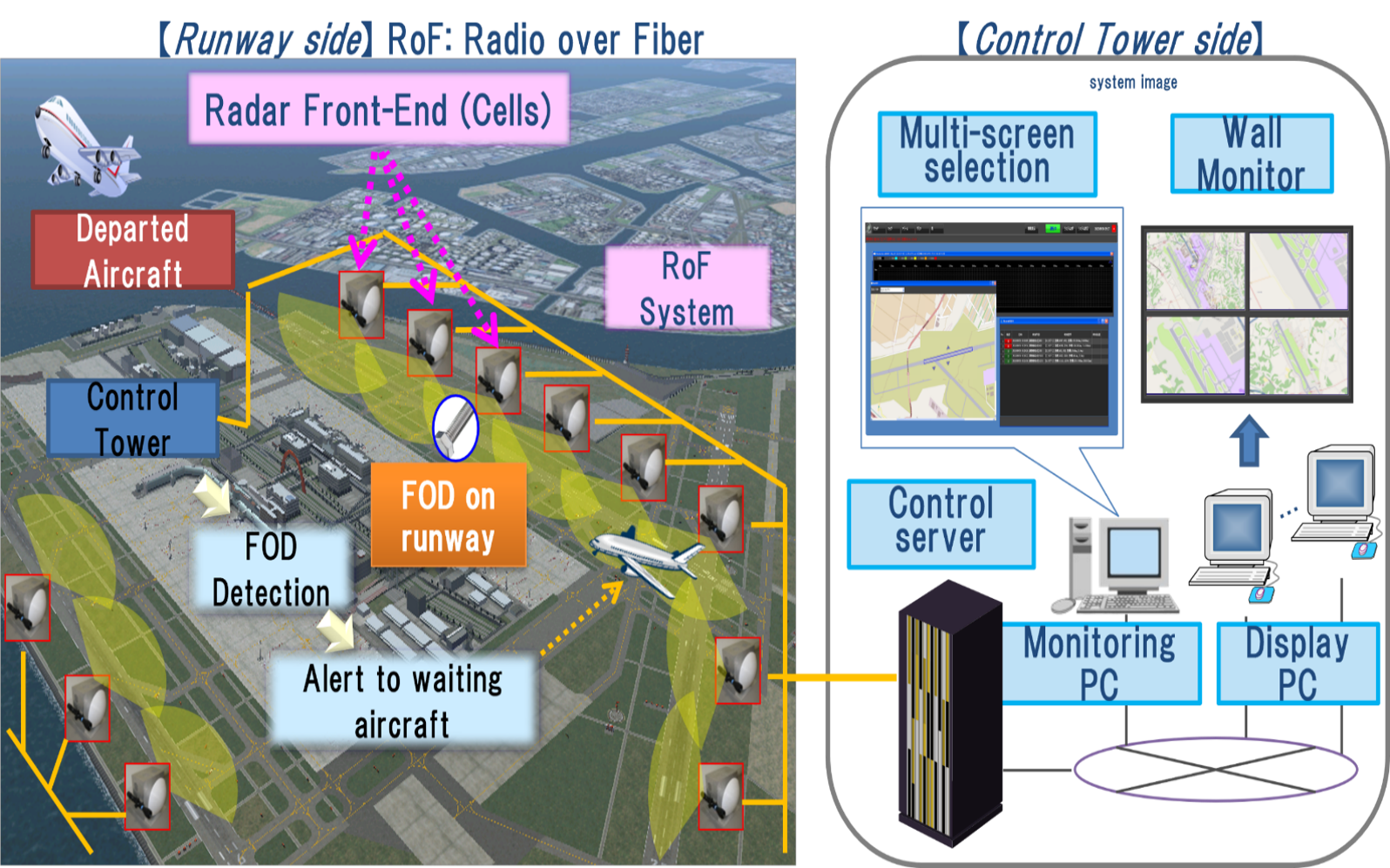

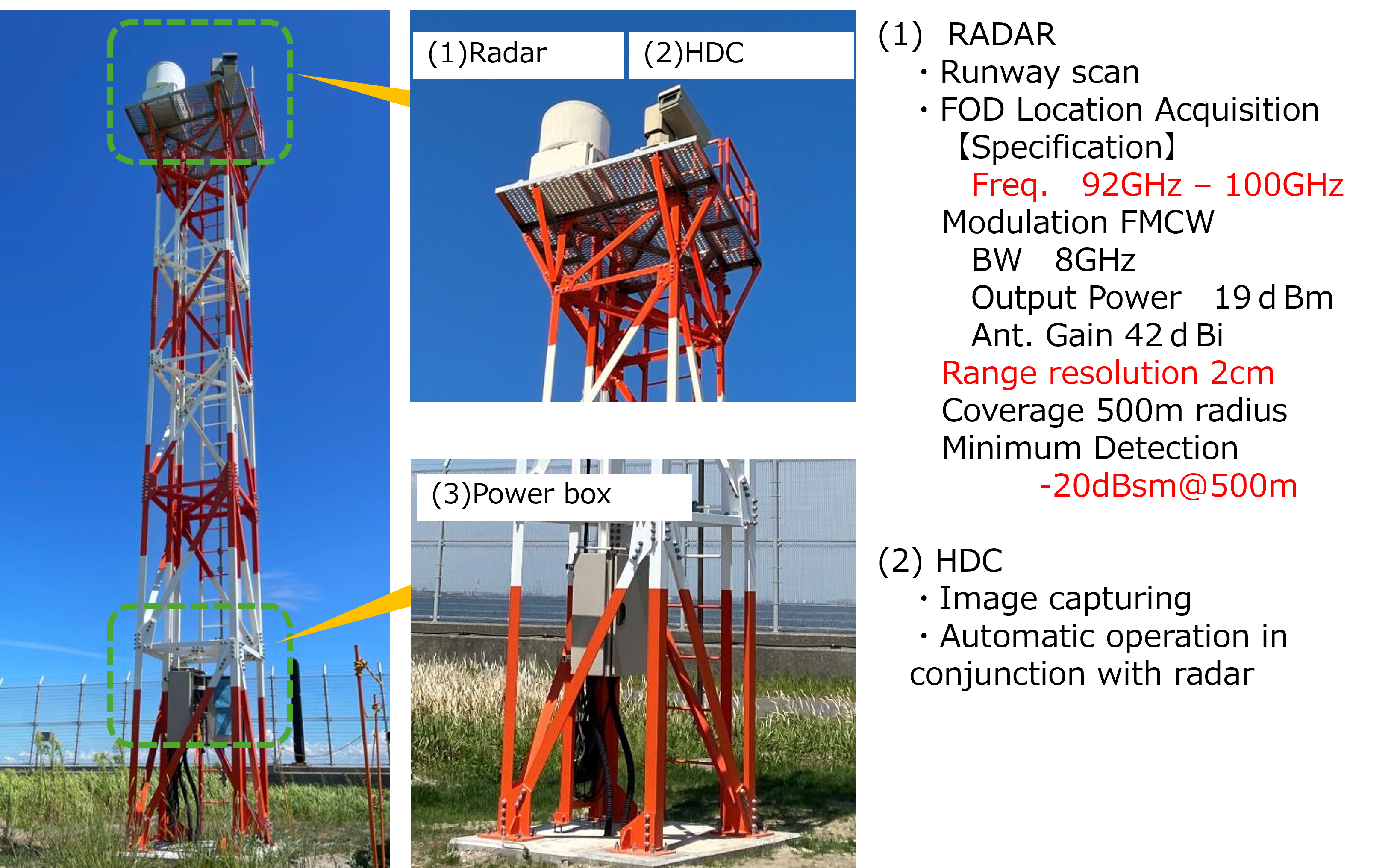

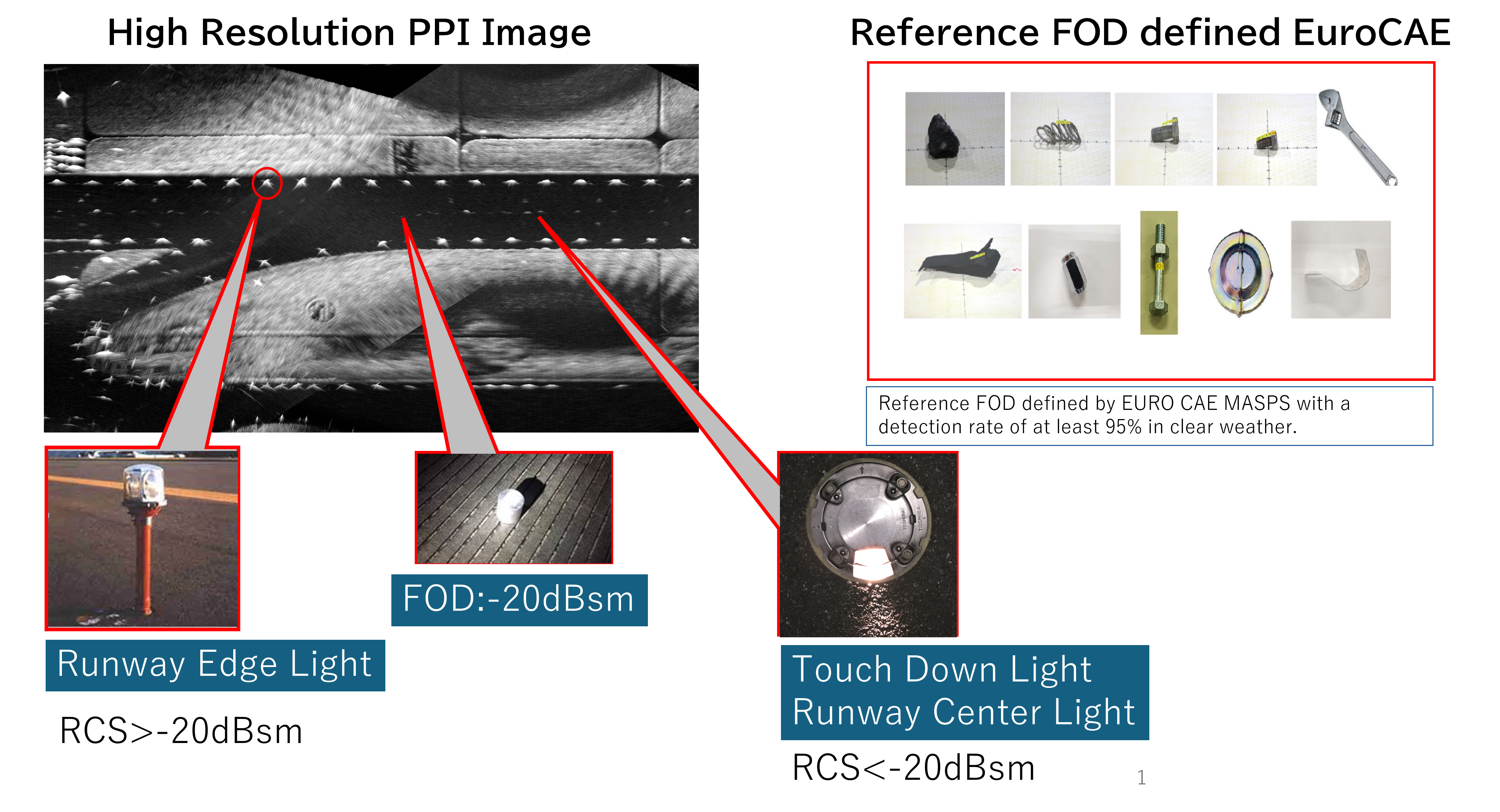

Modern airports handle hundreds of thousands oflandings and take offs annually. The high demand would require very precise airport operation to be carried out at a rapid pace. Aviation needs to adapt to the changing nature of risks since new risks could arise anytime which requires advancements in the airport safety and security efforts. One of the most critical airport’s safety risk is the presence of foreign object debris on the runaways. Kokusai Denki’s solution to this problem is its state-of-the-out Linear Cell Radar System Technology. It is a monitoring system that has the capability to detect foreign objects on the runway at a fast speed, supported with an automatic alert mechanism. We support airport operation with superior radar performance of unprecedented detection speed.

(Abstract)

The advantages of the system include its low operational cost, low emission of radio waves and most importantly a highly scalable system for busy airports. Better management not only increases efficiency, enhances safety and improves security, but also saves airports and airlines countless hours in time, money, and manpower.

Implementation Cost

Maintenance Cost

Registered Country

Environmental Categories

Best Practice and Technology

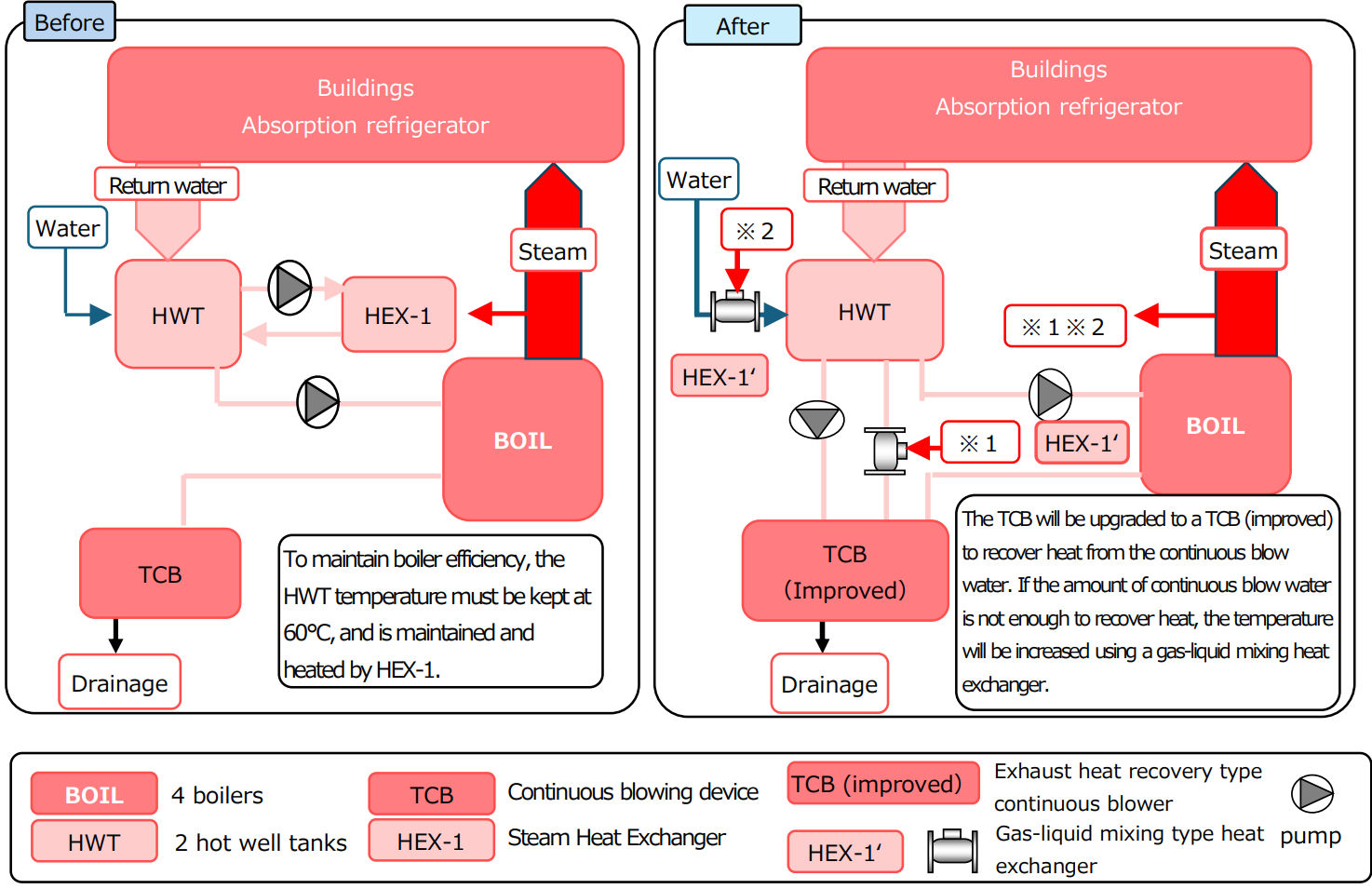

The energy center supplies each consumer with steam produced in a boiler as a heat source. To ensure stable boiler operation and steam quality, 3-5% of steam is discharged through a continuous blower. The aim is to reduce CO2 emissions by recovering heat from this continuous blower and adding it to the boiler feedwater, thereby reducing the amount of steam used to preheat the feedwater.

Characteristics: Currently, continuous blowing is treated as wastewater. By installing a heat recovery heat exchanger, the heat from continuous blowing (approximately 180℃) can be effectively recovered continuously.

Effect: CO2 reduction of approximately 200t-CO2/year.

(Abstract)

The system significantly reduces CO2 emissions by capturing waste heat from continuous steam blowing and repurposing it for boiler feedwater heating, enhancing energy efficiency at Tokyo International Airport.